Infrastructure and R&D

Infrastructure and R&D

Quality Assurance

Flex Tester is used in our R&D department to evaluate the durability and flexibility of PVC-coated fabrics under repeated bending. It ensures that our products meet high-quality standards and perform reliably in various applications

Innovation and Sustainability:

The Martindale Abrasion cum Pilling Tester in our R&D lab is utilized to assess the wear resistance and pilling behavior of our PVC-coated fabrics. This ensures our products maintain their appearance and performance even under rigorous usage conditions

Product Range:

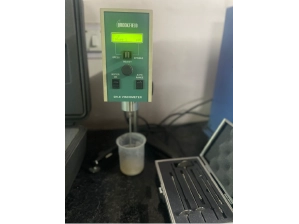

The Brookfield DV-E Viscometer in our R&D lab is an instrument for measuring the viscosity of our PVC paste and other materials. By precisely determining the flow characteristics, we ensure consistent quality and performance in our products, adapting formulations to meet specific application needs.

Customer Satisfaction:

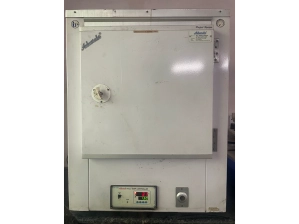

This laboratory electric oven, equipped with a precise PID temperature controller, is used in our R&D department to conduct various heat-related tests on PVC-coated fabrics. By controlling the temperature accurately, we can simulate different environmental conditions and evaluate the thermal stability, curing process, and performance of our materials, ensuring they meet the required industry standards.

Customer Satisfaction:

The Presto Tensile Testing Machine, part of our R&D lab's Jupiter series, is used to measure the tensile strength and elongation properties of our PVC-coated fabrics. By applying controlled tension, this machine helps us ensure that our materials can withstand the forces they will encounter in real-world applications, guaranteeing durability and reliability in our final products.